Production

Custom service

Sectors

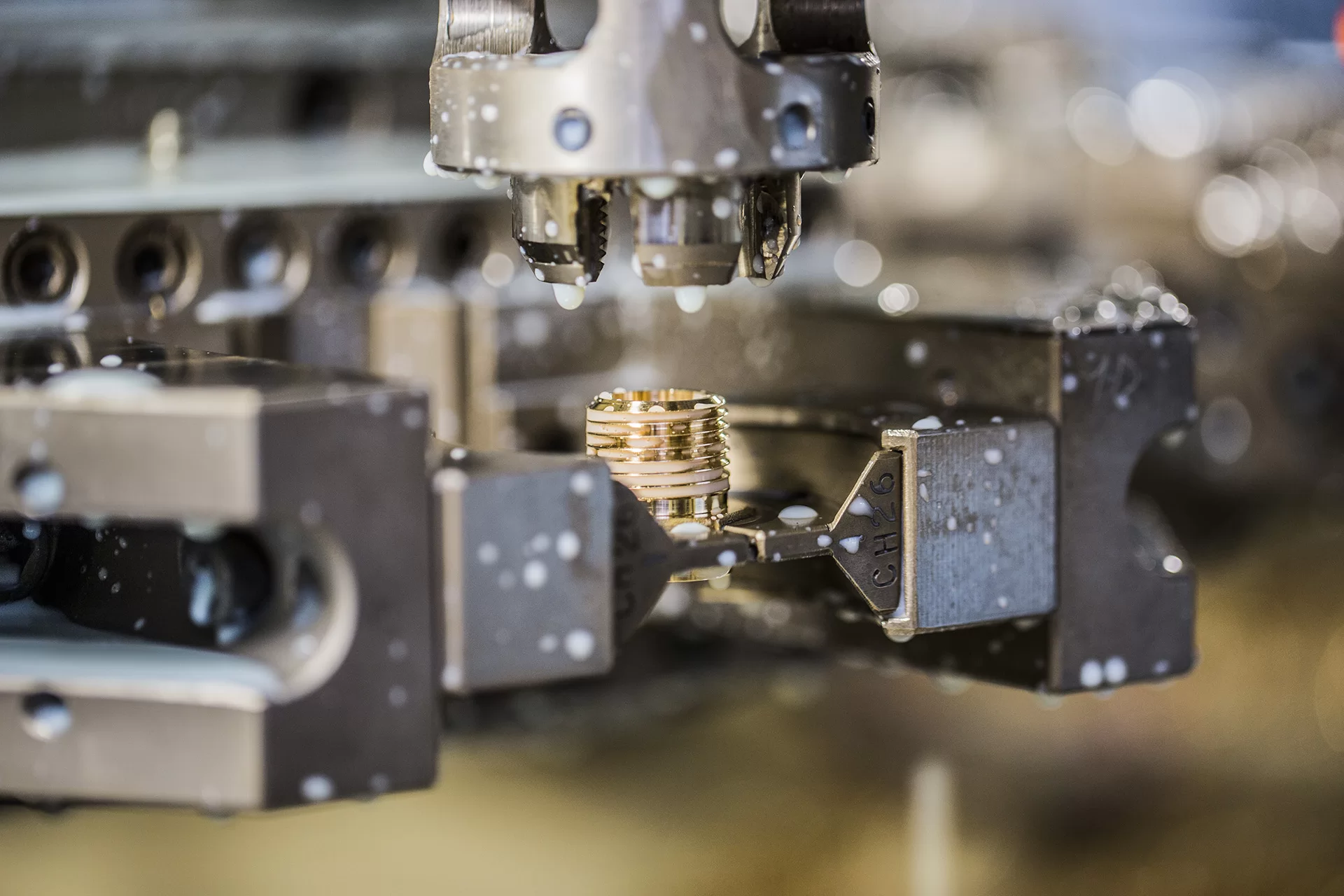

Customized products

Ferrero Valves

Technologies

Sustainability

News

Customized products