Production

Custom service

Sectors

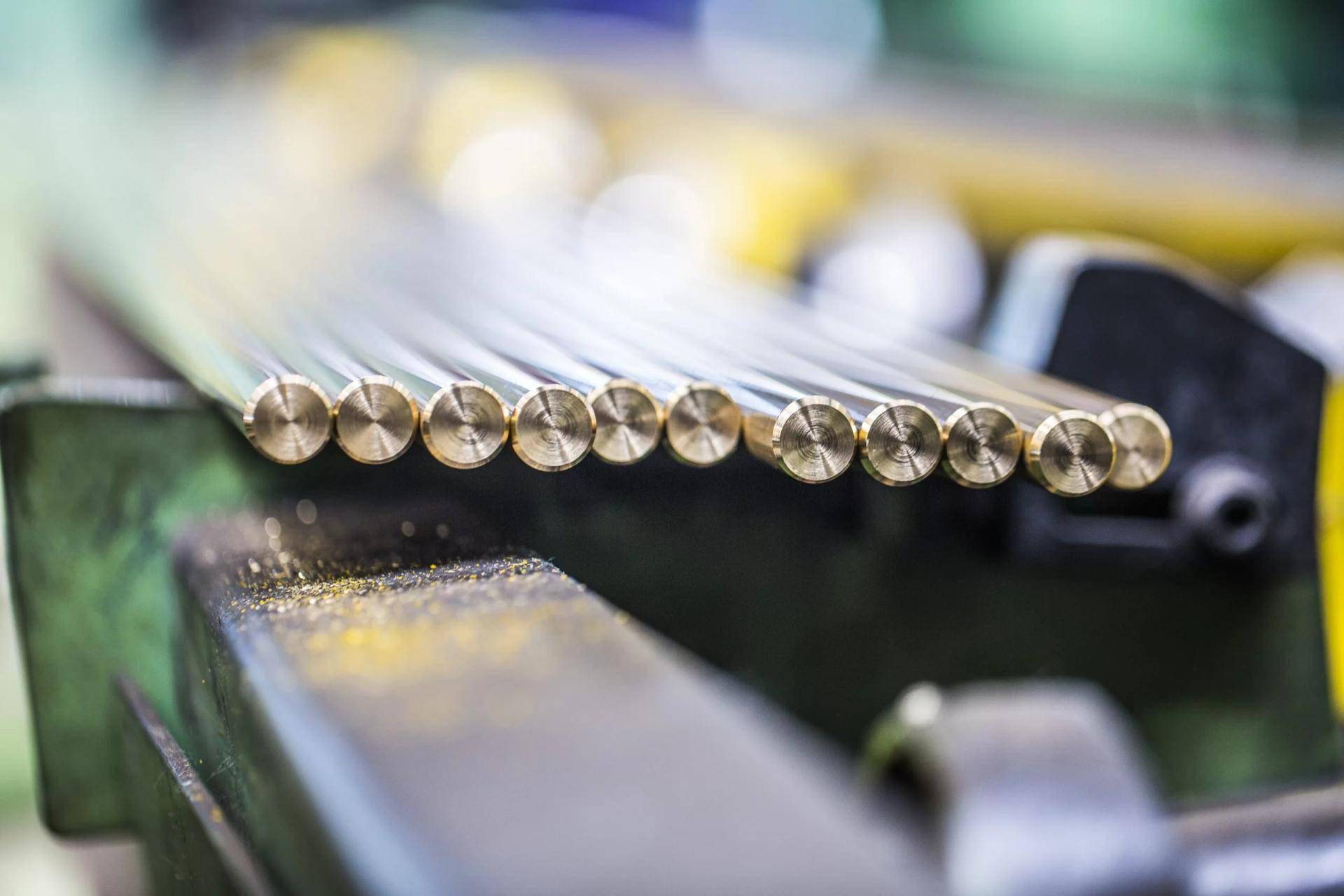

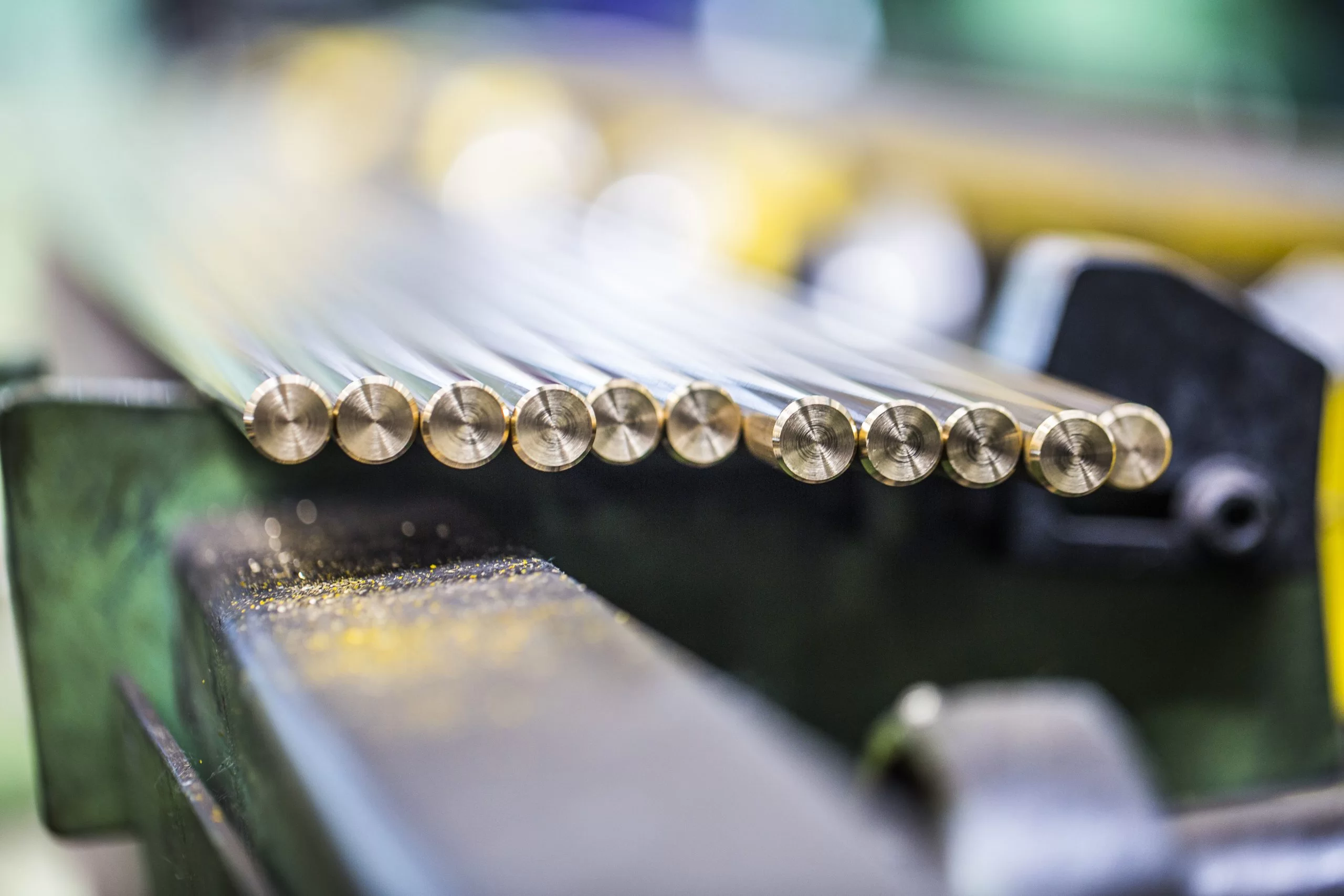

Customized products

Ferrero Valves

Technologies

Sustainability

News

Customized products